Ultimate Guide to Design Software for 3D Printing: Empowering Your Creative Business

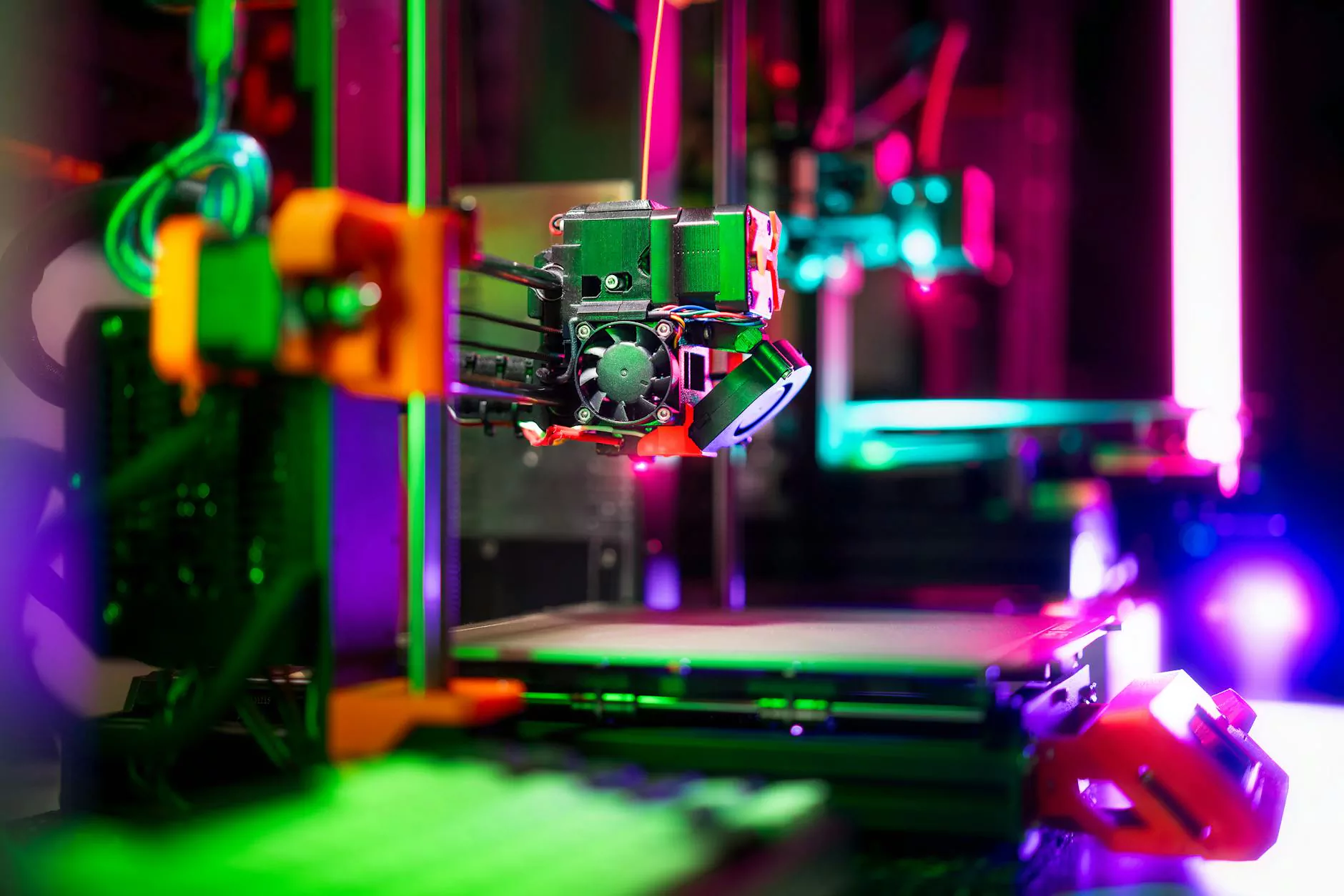

In today's rapidly evolving technological landscape, the 3D printing industry stands at the forefront of innovation, transforming how companies approach manufacturing, prototyping, and custom product development. Central to the success of any 3D printing business is the choice of design software for 3d printing. The right software not only enhances creative possibilities but also optimizes workflows, reduces errors, and accelerates time-to-market. This comprehensive guide explores everything you need to know about selecting and utilizing the best design software for your 3D printing endeavors, with particular emphasis on how businesses like 3dprintwig.com can leverage cutting-edge tools to boost productivity and innovation.

Understanding the Significance of Design Software in the 3D Printing Ecosystem

The design software for 3d printing acts as the fundamental bridge between an idea and its physical realization. It allows designers, engineers, and hobbyists to create detailed digital models which are then translated into instructions that 3D printers interpret for manufacturing. The choice of software impacts every stage of the product lifecycle—from initial conception, detailed design, simulation, to final production.

Key Features to Consider When Choosing Design Software for 3D Printing

Selecting an ideal design software for 3d printing involves evaluating several critical features:

- Compatibility with various file formats: Ensure the software supports formats like STL, OBJ, and AMF to facilitate seamless file transfer and compatibility with different 3D printers.

- Intuitive user interface: A user-friendly interface reduces learning curves and boosts productivity, especially for teams.

- Advanced modeling capabilities: Tools for parametric, freeform, or features-based modeling enable complex and precise designs.

- Simulation tools: Integrate features that allow for stress testing, material analysis, or motion simulation to ensure viability before printing.

- Support for lattice structures and infill patterns: Essential for optimizing strength-to-weight ratios and material usage.

- Customization and plugins: Expand functionality with add-ons and community-developed plugins for specialized needs.

- Cost considerations: Balance features against your budget, considering both free and paid options.

- Support and community: Robust technical support and an active user community facilitate troubleshooting and knowledge sharing.

Top-Rated Design Software for 3D Printing in 2023

The marketplace for design software for 3d printing is diverse, ranging from beginner-friendly tools to professional-grade CAD platforms. Here are some of the leading options recognized for their features, user experience, and industry adoption:

1. Autodesk Fusion 360

Autodesk Fusion 360 combines powerful parametric design, freeform modeling, and simulation into a unified platform. Its cloud-based environment allows for easy collaboration, making it ideal for small and medium-sized businesses. Integration with various 3D printers and export formats streamlines the manufacturing process.

2. Blender

Blender is a free, open-source 3D modeling suite renowned for its versatility. While primarily used for animation and artistic modeling, it also supports detailed engineering designs suitable for 3D printing. Its extensive plugin ecosystem allows customization tailored for printing workflows.

3. Simplify3D

Although primarily a slicing software, Simplify3D also offers robust design editing features and supports a wide range of 3D printers. Its advanced control over print settings helps optimize parts for strength, detail, and material efficiency.

4. Tinkercad

Tinkercad by Autodesk is a browser-based, beginner-friendly CAD tool. Its intuitive interface makes it ideal for educational purposes, hobbyists, and rapid prototyping. Despite its simplicity, it provides sufficient features for basic 3D printing designs.

5. Netfabb by Autodesk

Focused on preparing and repairing models for 3D printing, Netfabb offers advanced analysis, repair, and optimization tools. Its capabilities are geared toward ensuring that designs are free of defects and optimized for production runs.

Integrating Design Software for 3d Printing into Your Business Workflow

Successful 3D printing businesses strategically incorporate design software into their operations to maximize efficiency and output quality. The workflow typically includes:

- Conceptualization and sketching: Using CAD or creative modeling tools to develop initial ideas.

- Detailed modeling and refinement: Applying advanced features for precision and complexity.

- Simulation and testing: Running stress tests and analyzing structural integrity.

- Preparation for printing: Using slicing software or repair tools to generate optimized print files.

- 3D printing process: Transferring instructions to the 3D printer, monitoring, and troubleshooting as needed.

- Post-processing and quality assurance: Finishing, assembling, and verifying components meet specifications.

Integrating these stages with the right software solutions results in streamlined production, reduced material waste, and superior end products. Automation and cloud-based collaboration further enhance efficiency.

Future Trends in Design Software for 3D Printing

The evolution of design software for 3d printing continues to accelerate, driven by advancements in artificial intelligence, machine learning, and material science. Upcoming trends include:

- AI-powered design optimization: Algorithms that automatically refine designs for strength, weight reduction, or material usage.

- Generative design tools: Software that explores countless design permutations based on specific constraints, helping create innovative structures.

- Real-time simulation and feedback: Integrating live analysis to predict issues before printing begins.

- Cross-platform collaboration: Seamless integration of design, simulation, and manufacturing across different devices and teams.

- Material-aware modeling: Software that intelligently adapts designs based on the properties of the chosen printing material.

Embracing these trends will empower businesses to stay ahead in the competitive 3D printing arena, fostering innovation, reducing costs, and enabling entirely new applications.

How 3dprintwig.com Can Elevate Your 3D Printing Business with the Right Design Software for 3D Printing

As a business specializing in 3D Printing, leveraging the most effective design software for 3d printing is crucial. 3dprintwig.com offers a comprehensive range of services, insights, and tools to help your enterprise excel. Whether you're embarking on prototyping, custom manufacturing, or large-scale production, selecting the appropriate software enhances your capabilities.

- Expert Consultation: Guidance on choosing the software best suited to your business needs.

- Workflow Optimization: Integrating design tools seamlessly into your existing processes to streamline operations.

- Training Services: Educating your team on advanced features and best practices.

- Software Development and Customization: Tailoring design tools to fit unique project requirements.

- Latest Industry Insights: Staying updated with emerging technologies and trends.

Partnering with 3dprintwig.com ensures your business remains at the cutting edge, maximizing productivity and innovation through superior design software for 3d printing.

Conclusion: Unlock Limitless Possibilities with the Right Design Software for 3D Printing

The competitive edge in the 3D printing industry hinges significantly on your choice and implementation of design software for 3d printing. By selecting tools that align with your operational goals, embracing emerging trends, and integrating them seamlessly into your workflow, your business can unlock unparalleled levels of creativity, efficiency, and quality. Remember, the landscape is constantly evolving; staying informed and adaptable is key to maintaining your leadership position.

Whether you're a startup exploring the potentials of 3D printing or an established enterprise seeking to optimize your manufacturing processes, a strategic investment in top-tier design software is fundamental. Partnering with industry experts like 3dprintwig.com can provide you with the insights, tools, and support necessary to thrive in this innovative industry.